An air leak test system to confirm the sealing and waterproof performance.

An air leak test system to confirm the sealing and waterproof performance.

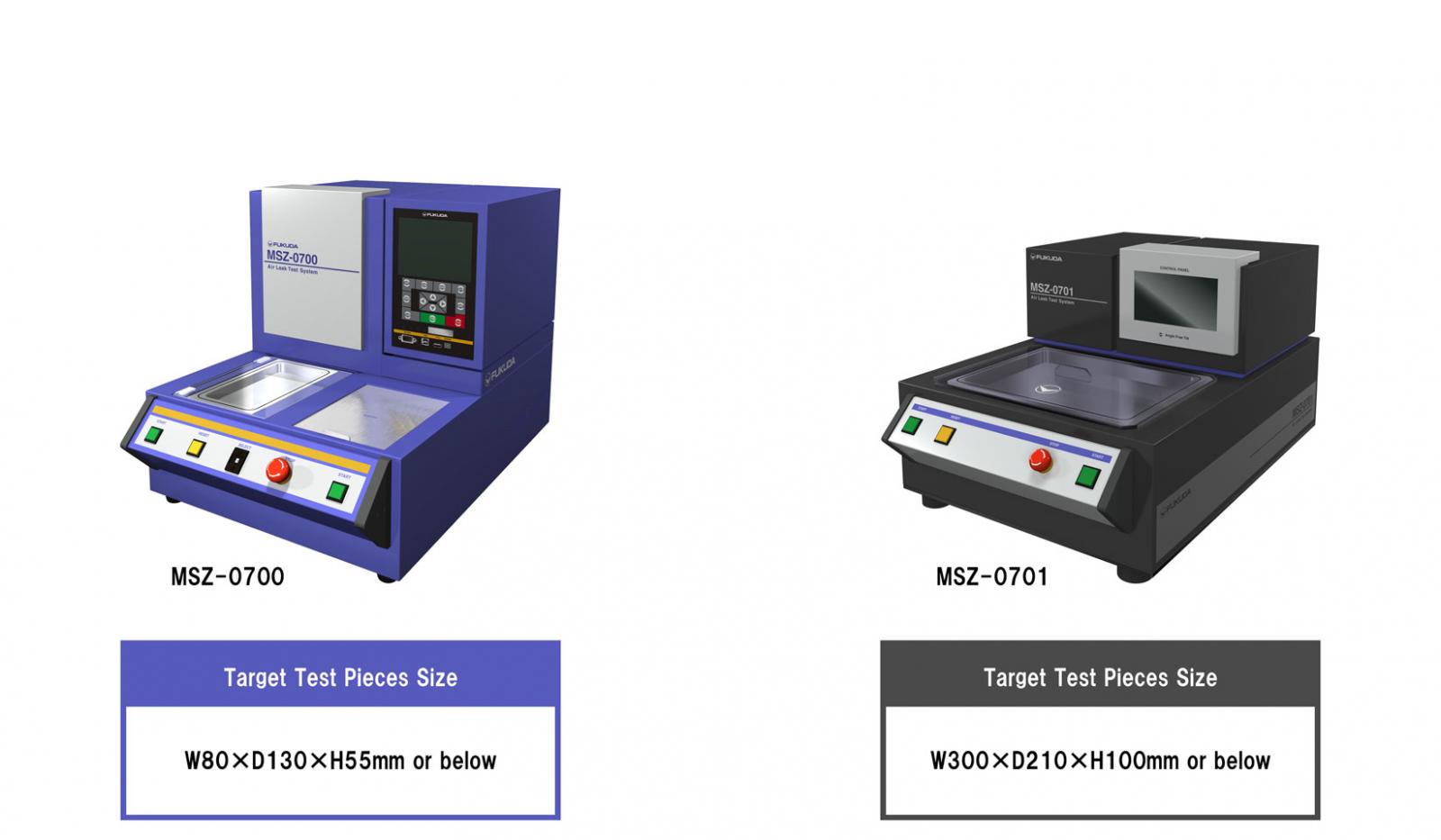

Characteristic of MSZ series

・Leak tests equivalent to IPX7 and IPX8 (waterproof standards) are possible

・The high accuracy and efficiency the waterproof test by the air leak test

・Line-Up corresponding to the work size

Target test piece example

This device can conduct leak tests on a wide range of sealed items.

・Automotive Parts

Dashboard Camera,Back Camera,Smart Key,ECU,LED Light

・Electronic Device (Home Appliance / Medical / Beauty Appliance / Healthcare Appliance)

① Information Appliance / Communication Home Appliance

Smartphone,Mobile Phone,Wireless Device,Wireless Charger,Wearable Device (E.g. Wearable Watch, Smart Glass, Headmounted Display),Tablet Terminal,Compact Notebook PC,Handy Terminal,IC Tag

② Home Appliance / AV Home Appliance

Insulin Pump,Hearing Aid,Facial Device,Health Device,Remote Control

③ Others

Digital Camera,Measuring Instruments (E.g. Portable Type, Outdoor Use),Foot Pedal,Batteries *

*Pouch type lithium batteries have strict inspection conditions, please consult us before purchasing.

・Electronic components

Small Motor,Relay,Sensors (E.g. Automotive, Accuracy Meter, Distance Meter),Waterproof Connector

・Packaging Containers (Food / Cosmetic)

Bottle Container,Resin Bottle,Glass Bottle,Cosmetic Container,Pillow Packaging & Stick packaging (E.g. Confectionery, Powdered Beverages, Wet Tissues, Alcohol Wipes)

・At least 1 mL of internal volume is required in a test piece.

・This is just an example, please contact us regarding measurement availability.

The MSZ Series is an air leak testing device able to test the water tightness of the sealed items.

The MSZ Series is an air leak testing device able to test the water tightness of the sealed items.

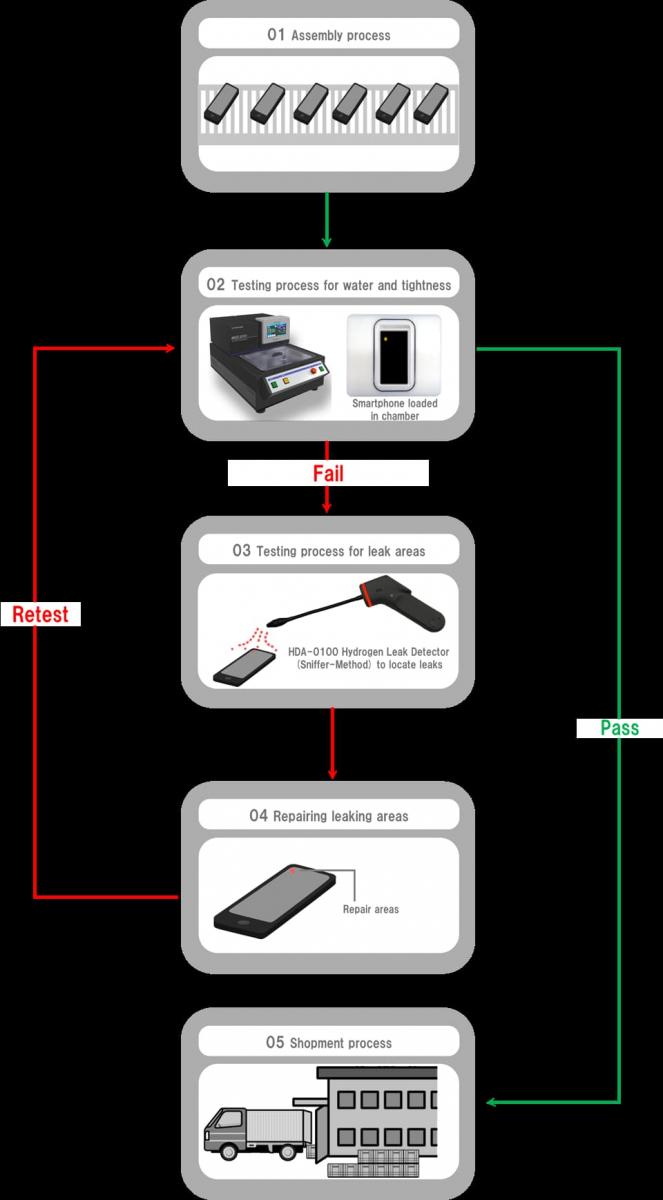

Testing Example: Smartphone

The MSZ Series has been developed as a testing device for water and air tightness in electronic equipment. The following chart shows the testing process model using a smartphone as an example.Smartphones assembled in manufacturing lines are shipped out after going through a range of testing procedures designed for quality assurance purposes. Testing for water and air tightness is one of the tests that are carried out in this procedure.

First, the smartphone required for testing is setup for testing on the MSZ series and then leak testing is commenced. The item is determined as being ready for shipping if it comes within the standard leak volume parameters set prior to the test. Smartphones that show a leak rate higher than the predetermined settings are considered faulty. At this point, areas that are found to be leaking are repaired in order for them to be put back into a state that they can be passed onto shipping. We recommend that leak testing for specific areas be carried out by the HDA-0100 (Sniffer-Method) unit. ≫Testing process for leak areas

Once the leak area is specified, carry out the necessary repairs. Then set the repaired item into the MSZ series to retest for leaks. The item may shipped if it passes the test and is determined as being non-faulty.

*The area around the speaker must be covered with a seal during this test as this area will always be subject to leaks.

Testing waterproof performance with air leak tests

Generally, waterproof tests are carried out by sinking workpieces or measuring strain amount. Human errors occur easily in sinking tests as numerical control is difficult, and extra processes such as drying are necessary. Moreover, tests using strain amount have low correlation with the leak amount, therefore conversion to air or water leak amounts is not possible. As such, the setting of test specifications is based on the actual workpiece, raising issues with the rationality, adequateness and commonality of the setting values. In contrast, the air leak test is a dry method that directly measures the air leak amount, therefore conversion to water leak amount is easy and is highly advantageous towards specification settings due to the rationality and adequateness of the setting value.

Quality control using air leak amount

Waterproof standard by IP code are not quantitative. You can perform quality control more efficient by using quantified data by the air leak tester.

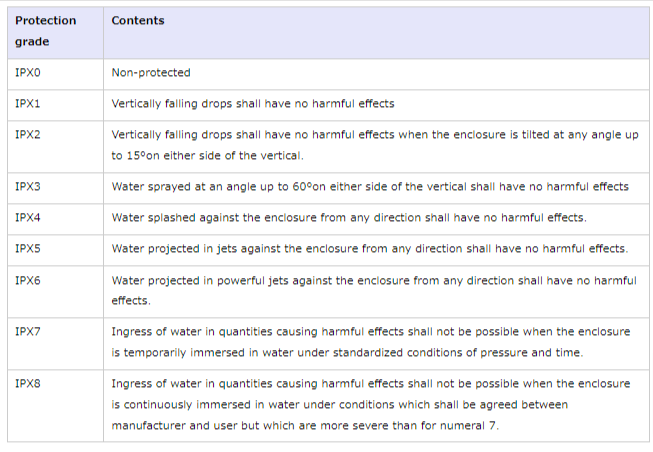

IP Code – Excerpt from JIS C 0920 (2003). Please refer to the JIS standard for details.

Air leak test equivalent to IPX7 and IPX8

Quantitative waterproof test

IPX7・8 are defined to be “Ingress of water in quantities causing harmful effects shall not be possible” In order to perform a quantitative test, must be determined as a numerical value, the “water leak amount causing harmful no effects.” Then Water leak amount can be converted into air leak amount. By determining the numerical value, waterproof test with the air leak test is possible.

Measurement methods

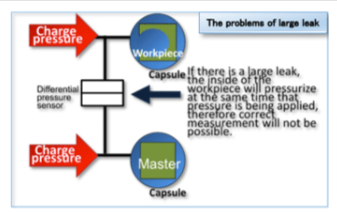

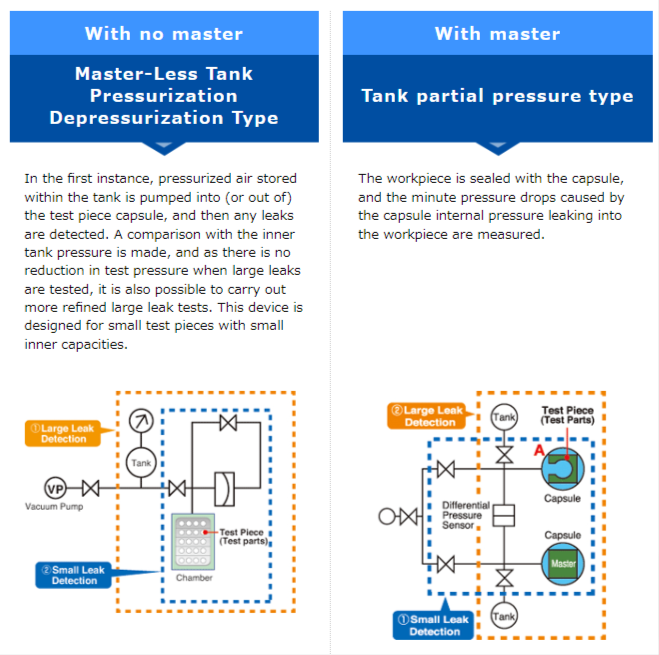

Products with a waterproof feature are sealed therefore have no opening through which pressure can be applied. If this is the case, the workpiece is put inside a capsule, to which pressure is then applied. Leaks are detected because the internal pressure of the capsule drops if there are leaks.Leak tests for sealed products must include both large leak measurement and small leak measurement. If there is a large leak, the inside of the workpiece will pressurize at the same time that pressure is being applied, therefore correct measurement will not be possible. There are 2 types of leak tests for sealed products; tank partial pressure type and tank pressurization type. The appropriate type should be chosen to suit workpiece characteristics.

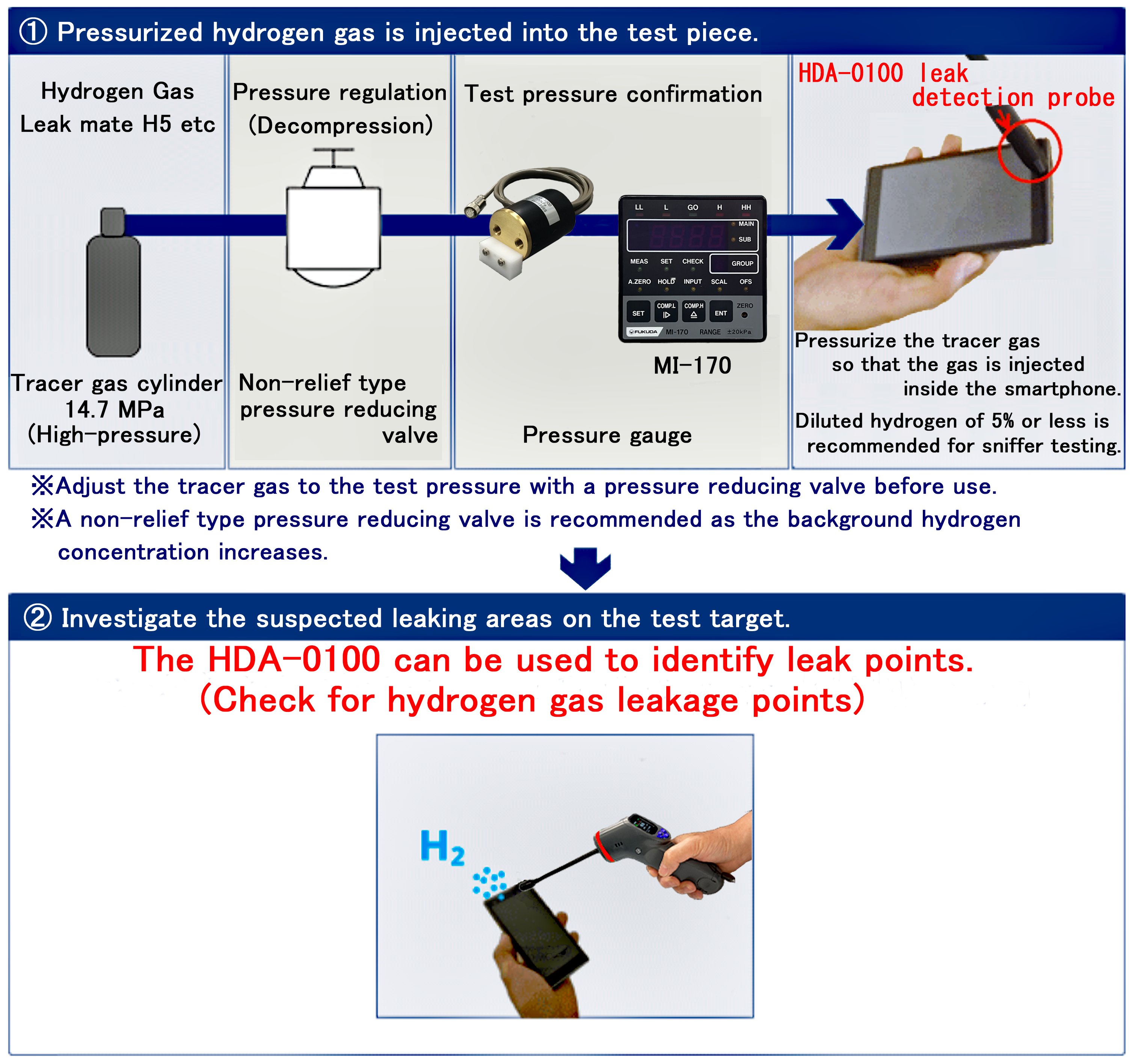

Leak area testing process HDA-0100 (Sniffer-Method)

A hydrogen leak test will be necessary using an HDA-0100 (Sniffer-Method) in order to identify areas where leaks are occurring in goods that have been determined as faulty using the MSZ series. Tracer gas with 5% hydrogen is used for this testing method.

≫Click here for hydrogen leak testing principles

Diagram 2 shows a leak testing model using the sniffer-method.

The test target is pressurized with tracer gas (hydrogen 5% + nitrogen 95%). Then the tip of the probe is placed directly in the area to be tested, and the leak test is carried out by detecting any hydrogen escaping from the leaking area. The probe is a suction type model with its own built in air pump with a rate of 30ml/min.

Testing model Example: Smartphone